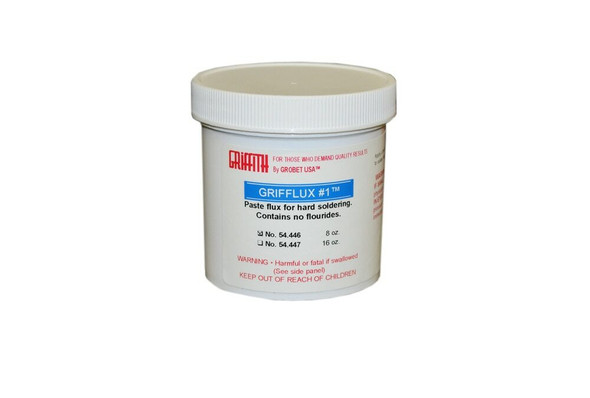

Description

Expires on March. 2023 (Some are opened, but they are still good to be used)

Size: 1lb.

Country of origin: United States

Used by silversmiths, this long-lasting white paste flux won’t break down from prolonged heating--a staple for every bench. Use when soldering or brazing gold, silver, brass, copper and other non-ferrous metals; effective from 1,100°–1,600°F (593°–871°C). Contains fluorides, potassium and hydroxide.

How To Solder More Successfully

These tips can help you solder more successfully and more reliably . . . every time. They are so simple, but it can be too easy to let the little things slip our minds as we work through our processes.

The Basics On How To Solder Effectively

Here's how to solder effectively using the basic skills for soldering. Follow these steps to ensure strong, long-lasting joint.

Solder won’t flow on a dirty or greasy surface. Use a de-greasing detergent cleaner and an abrasive pad, or an abrasive such as pumice powder to remove dirt or grease from the metal being soldered. Rinse thoroughly after cleaning. You can also steam-clean the workpieces.

Components, findings and joints must fit tightly together. Gaps in joints and poorly matched junctures between parts create a poor solder joint, which could result in pitting of the solder or in a weak joint that could break. Occasionally, solder simply will not fill a poor-fitting area.

Flux prepares the metal surface to receive the fluid solder. When applying flux, make sure it is in contact with the solder at all times and that it touches both metal parts being joined. Some self-pickling fluxes also help dissolve oxides. Keeping the joint oxide-free is important for creating the ideal soldering surface.

Use either a neutral flame (equal parts oxygen and gas) or a reducing flame (more gas than oxygen). The metal adjacent to the joint must reach the necessary temperature before solder will flow. First concentrate the heat on the surrounding surface, then on the joint to be soldered. Remember, solder flows to the hottest part of the surface and toward the flame.

After soldering, use a mild acid pickle to clean nonferrous metals. This removes oxides and other soldering residues prior to finishing. When storing solders, keep them free from dirt and grease. Sheet solders may be cleaned to remove dirt or residue.